Prefabricated construction originated in major developed countries in the West after World War II. After more than half a century of development, it has become the main architectural development model in major developed countries such as the United States, Japan, and France, and is currently the mainstream of the international construction industry.

& nbsp; & nbsp; Prefabricated construction originated in major developed countries in the West after World War II. After more than half a century of development, it has become the main architectural development model in major developed countries such as the United States, Japan, and France, and is currently the mainstream of the international construction industry. Prefabricated buildings have developed to a relatively mature and complete stage in developed countries such as Europe, America, and Japan. Japan, the United States, Australia, France, Sweden, and Denmark are the most typical countries. Japan is the first country to mass produce residential buildings in factories. Currently, 85% of high-rise residential buildings in Japan are constructed using prefabricated methods; The United States emphasizes the comfort, diversity, and personalization of residential properties. Other countries have chosen their own paths and approaches based on their respective economic, social, industrialization level, natural conditions, and other characteristics. In terms of standards, the United States has ASTM C920 and Japan has JIS A5758 standards. This issue will provide some analysis on the situation of these two standards< br />

nine hundred

& nbsp; & nbsp; Analysis of ASTM C 920 Standard in the United States

& nbsp; & nbsp; The ASTM C920 standard for elastic joint sealant was released in 2008. This standard is similar to ISO11600, but not equivalent to ISO11600. Many of its indicators and requirements differ significantly from ISO11600. This standard is also classified based on the displacement ability of the sealant, divided into several levels such as 12.5, 20, 25, 35, 50, etc., but there is no distinction between high and low modulus. This standard specifies the sag degree (4.4 ℃ and 50 ℃); Under 2 ℃ conditions, the construction performance includes extrusion performance, surface drying time, and other basic properties such as hardness and thermal weight loss. The regulations for adhesion include adhesion under dynamic cycling, peel adhesion, and adhesion after immersion in water. The requirements for immersion are relatively high, with Level 1 requiring immersion for 6 weeks and Level 2 requiring immersion for 10 weeks. In addition, this standard specifies pollution and color changes. For the adhesive used in the assembly of building exterior wall joints, this standard considers the effects of temperature, displacement changes, water immersion, and other factors on the joint sealant, as well as pollution, but does not take into account the effects of modulus and ultraviolet light exposure. This standard is not like the ISO11600 standard, which lists data tables for each level of migration. Therefore, the author has compiled the technical specifications requirements for Grade 25 sealant, as shown in Table 1.

Table 1 ASTM C920 (Class S, Grade 25) Technical Indicators Table

nine hundred and one

& nbsp; & nbsp; Analysis of Japanese JIS A 5758 Standard

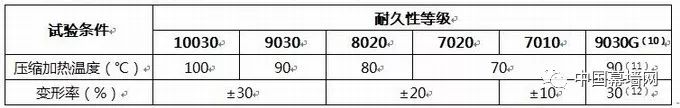

& nbsp; & nbsp; The JIS A 5758 "Building Sealing Materials" standard was established in 1979 and has undergone multiple revisions since then. It was discovered that it was revised again in 2004. The revision was based on the ISO11600-2002 standard. The technical specifications of this standard are basically consistent with ISO11600-2002 standard, except for the addition of durability indicators. Durability is divided into several levels based on compression heating temperature and deformation rate, such as 7010, 7020, 8020,

0, 10030, etc. The durability testing of this standard considers multiple influencing factors such as temperature, water, static tensile compression, dynamic tensile compression, etc. The testing period is over 42 days, and the overall requirements are relatively high. However, the impact of ultraviolet light was not taken into account. There are also no pollution related indicators.

Table 2 Technical Indicators of JIS A 5758 Standard

nine hundred and two

& nbsp; & nbsp; Note: (8) Water based joint filler is below 25

& nbsp; & nbsp; Regulations on Durability Level

& nbsp; & nbsp; The durability level is shown in Table 3. For the combination marked with ○ in Table 5, the test shall be conducted in accordance with JIS A 1439, 5.17, and then cut

& nbsp; & nbsp; The presence of obvious abnormalities such as dissolution, expansion, cracking, or peeling in the three test samples of the adhesive is used as a judgment of qualification.

& nbsp; & nbsp; Table 3 Durability Level

nine hundred and three

& nbsp; & nbsp; (11) Indicating the stretching heating temperature

& nbsp; & nbsp; (12) Representing the rate of tensile deformation

Table 4 Durability Test Procedure

nine hundred and four

0, 10030, etc. The durability testing of this standard considers multiple influencing factors such as temperature, water, static tensile compression, dynamic tensile compression, etc. The testing period is over 42 days, and the overall requirements are relatively high. However, the impact of ultraviolet light was not taken into account. There are also no pollution related indicators.

0, 10030, etc. The durability testing of this standard considers multiple influencing factors such as temperature, water, static tensile compression, dynamic tensile compression, etc. The testing period is over 42 days, and the overall requirements are relatively high. However, the impact of ultraviolet light was not taken into account. There are also no pollution related indicators.